DIGITAL TWIN

DIGITAL TWIN

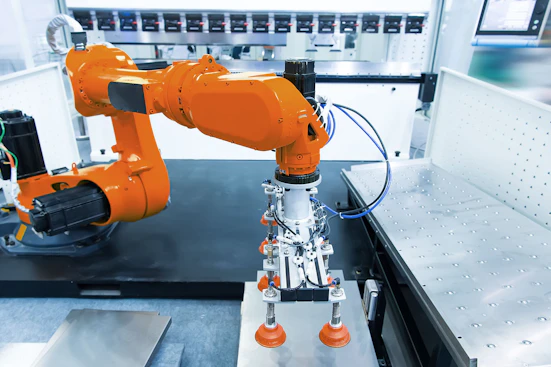

The idea behind a digital twin is to map the entire lifecycle of an object in the digital world - from the approach and production to delivery and operations and down to end of use. Information can thus be exchanged more quickly and between all overarching parties (manufacturers, operators, service partners), laying the foundation for new business models.

In addition, the perspectives of both manufacturers and operations can both be mapped. In particular, these differ in that mechanical engineers are primarily focused on enabling data exchange with machines; however, facility operators are more likely to be interested in integrating machines from different manufacturers into an existing production process.

A CENTRAL ASPECT OF GENERATING ADDED VALUE FROM THE DIGITAL TWIN IS TO CONNECT IT TO REAL-TIME MACHINE DATA AND DATA FROM THE ERP SYSTEM.

DIGITAL TWIN - OUR APPROACH

To ensure a practical, economic introduction of the digital twin, we rely wherever possible on standards such as SAP AIN, industry standard OPC UA or the SAP Cloud Platform/Microsoft Azure in the cloud area. We use these standards as a foundation for our customer-specific solutions.

Our consulting services for IT, technology and processes are therefore highly related to implementation and application.

The concept of a digital twin is new for many companies. To gain acceptance of it within an organisation and obtain and maintain the commitment necessary for such a project, quick, tangible results are important. For this purpose, we rely on design thinking methods. This means that we assist you in defining problems and use cases, and then in evaluating them and building suitable solutions. In addition, we use agile methods to implement projects.

We have designed a series of workshops about the digital twin to help you get started with it within a context exactly suited to you.